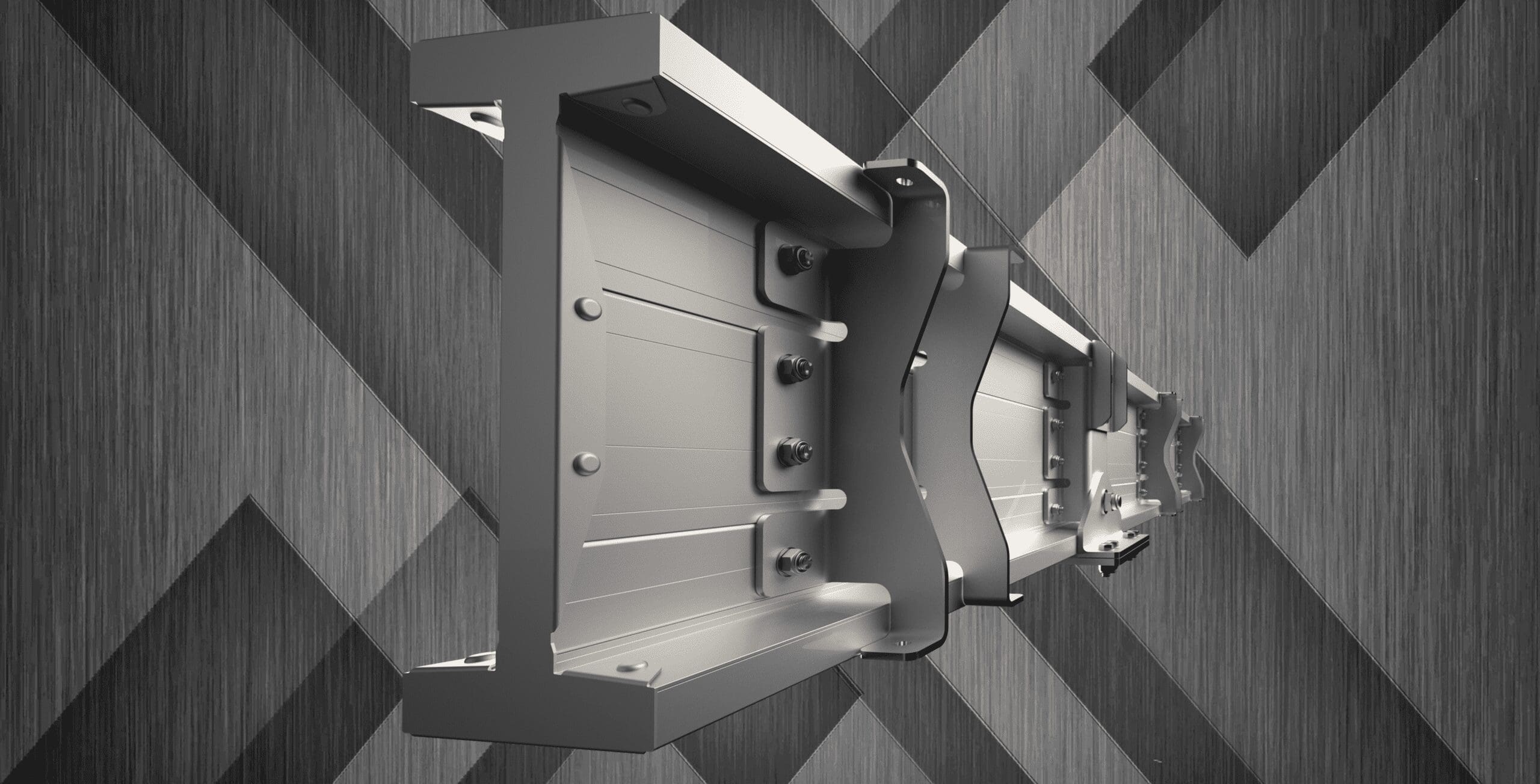

XBEAM

Faster. Lighter. Stronger. Its’ the beam, raising the bar.

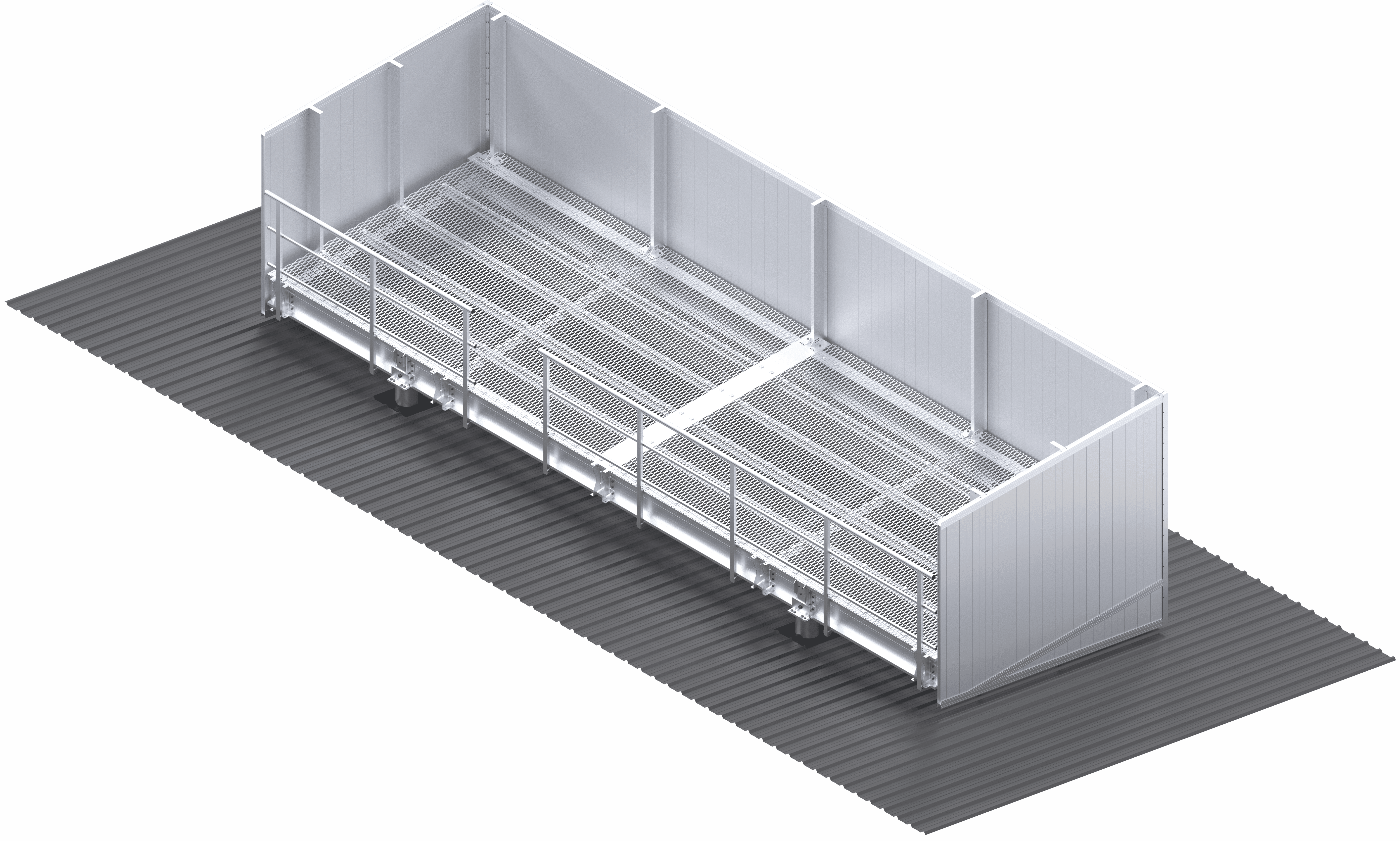

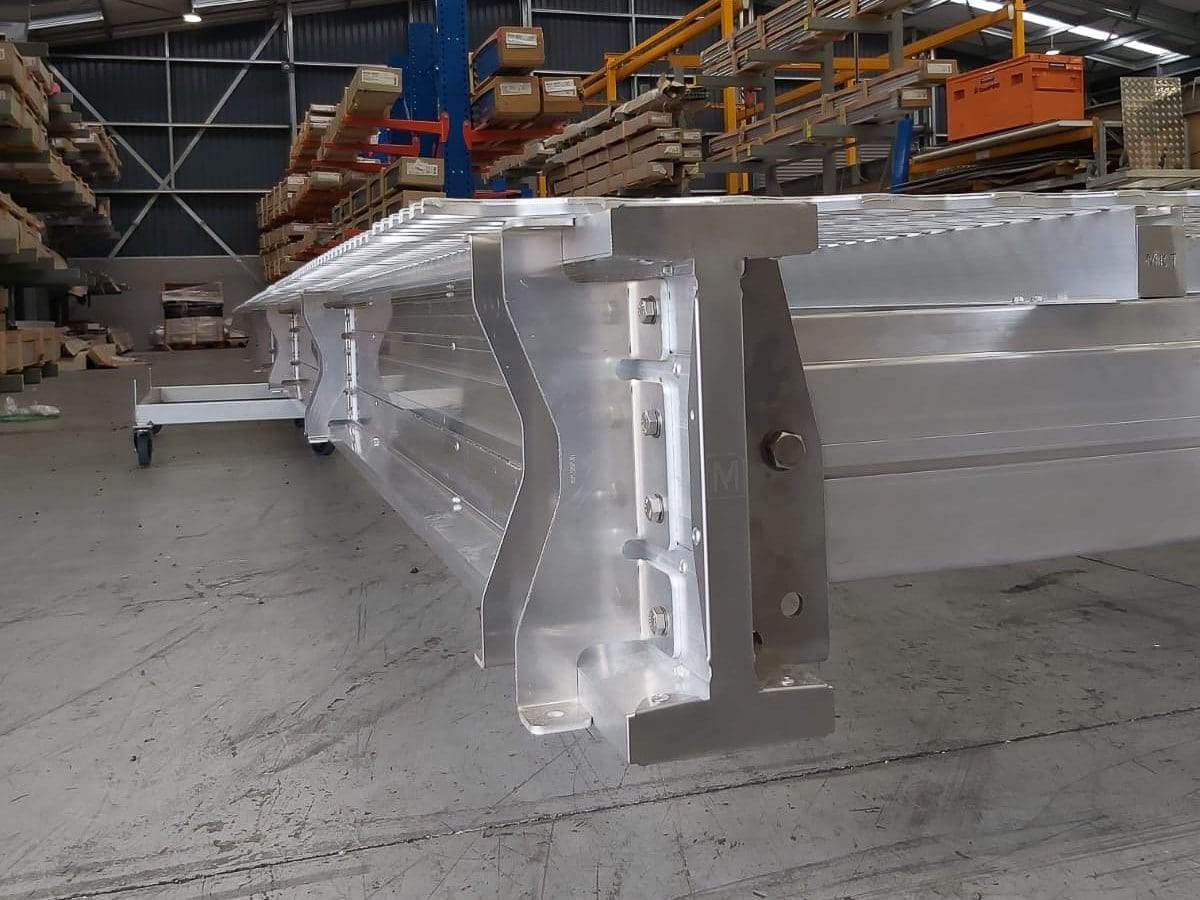

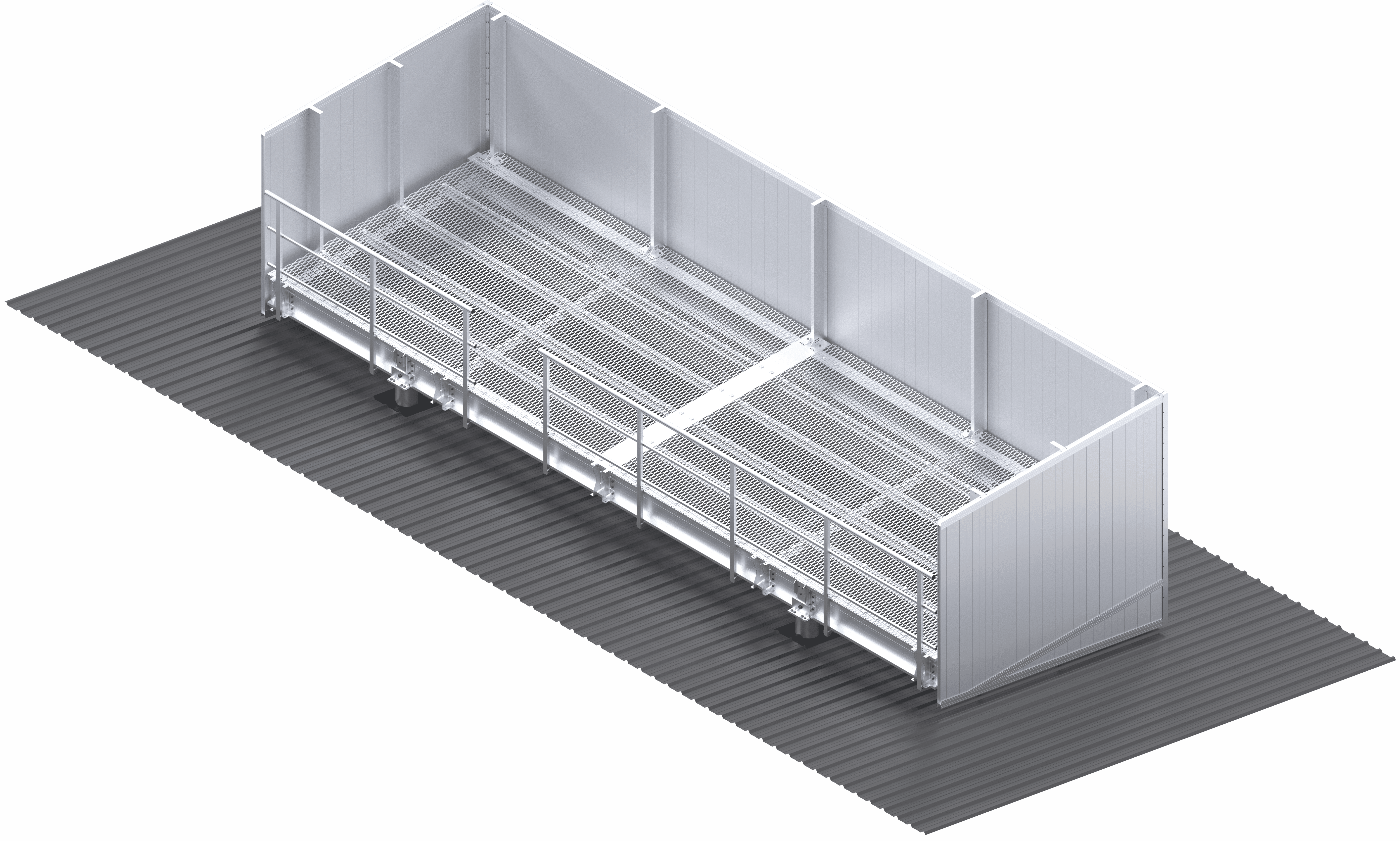

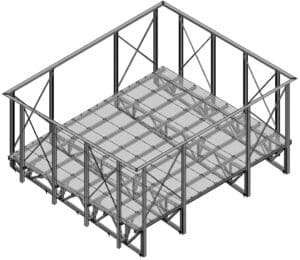

A configurable aluminium beam system utilised in a modular XBEAM platform system.

1

3

4

COMPLIANCE

DOWNLOADS

Unpacking XBEAM

Which fixing is best for my roof?

No Backstays

FAQ’S

Do you also take care of the waterproofing detail of the roof penetration?

Monkeytoe supplies the appropriately sized Dektite boot with our Stub leg kits, which should be installed by the main roofing contractor at the time of roof install. This typically means that the leg stubs are installed before the roof itself. On a retrofit project, if there is an existing roofing contractor then we recommend they be engaged to install the boots. If there are no roofers currently on the job then Monkeytoe can engage one for you.

Do the penetrations through the roof require a flashing detail?

Is the Xbeam a watertight unit?

Are there any concerns about dissimilar metals at hub portal connections, such as between zinc bolts, aluminium structures and steel beams? Are there any risks of galvanic corrosion?

In short, no. Where these connections are made inside a building, there are no concerns. For galvanic corrosion to occur, an electrolyte must be present to complete the electrical circuit. This should not be happening inside a building often enough for corrosion to happen. As an added precaution, however, Monkeytoe recommend using a lanolin moisture/corrosion inhibitor spray at the time of install to prevent any moisture from being trapped during construction. We have chosen zinc bolts for this application as they are more compatible with aluminium than galvanised fasteners are, and they maintain compatibility with the steel structure. Where this connection occurs in a weather-exposed area, isolation will be provided between all dissimilar metals to mitigate and prevent corrosion. This will typically be a thin rubber or hard plastic layer, but in some situations a specialised coating may be used.

Does Monkeytoe engineer and certify from portal up?

This is covered by a combination of physical testing as per AS/NZ 1170.0 Appendix B, as well as reference to the European composites code where applicable.

Where and how is carbon fibre incorporated into the Xbeam?

What testing has been completed for structural integrity in fire situations?

Is the XBEAM unit watertight?

While the Xbeam is watertight along the main length, the end caps aren’t a sealed fit. We are now looking at making the entire beams watertight by using a waterproofing foam in the ends of the cavities before installing the end caps.

Do you have the Fire resistance properties of these beams, such as the FLR Ratings?

How did we go about getting the capacities from the Xbeam? Was this through testing?

Check out this video which unpacks the Xbeam system…

WHAT FIXING IS BEST FOR MY ROOF?

Click on the below download for a quick guide of which fixing to use on which roofing profile/type

NO BACKSTAYS

No screening backstays means that you gain approx. 600mm of extra serviceable platform area, or it can allow you to reduce the overall platform size.

COMPLIANCE

This system is designed in accordance with Aluminium Structures, Part 1: Limit State Design AS/NZS 1664.1 Standards Australia / New Zealand NZS/AS 1657.

Fully documented third party testing to ensure compliance to the building code. These included deflection, horizontal, load and temperature and durability.