XBEAM

Faster. Lighter. Stronger. Its’ the beam, raising the bar.

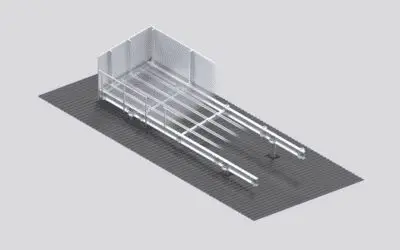

Monkeytoe XBEAM is a key to a revolutionary configurable aluminium beam system that is part of our Modular XBEAM platform system.

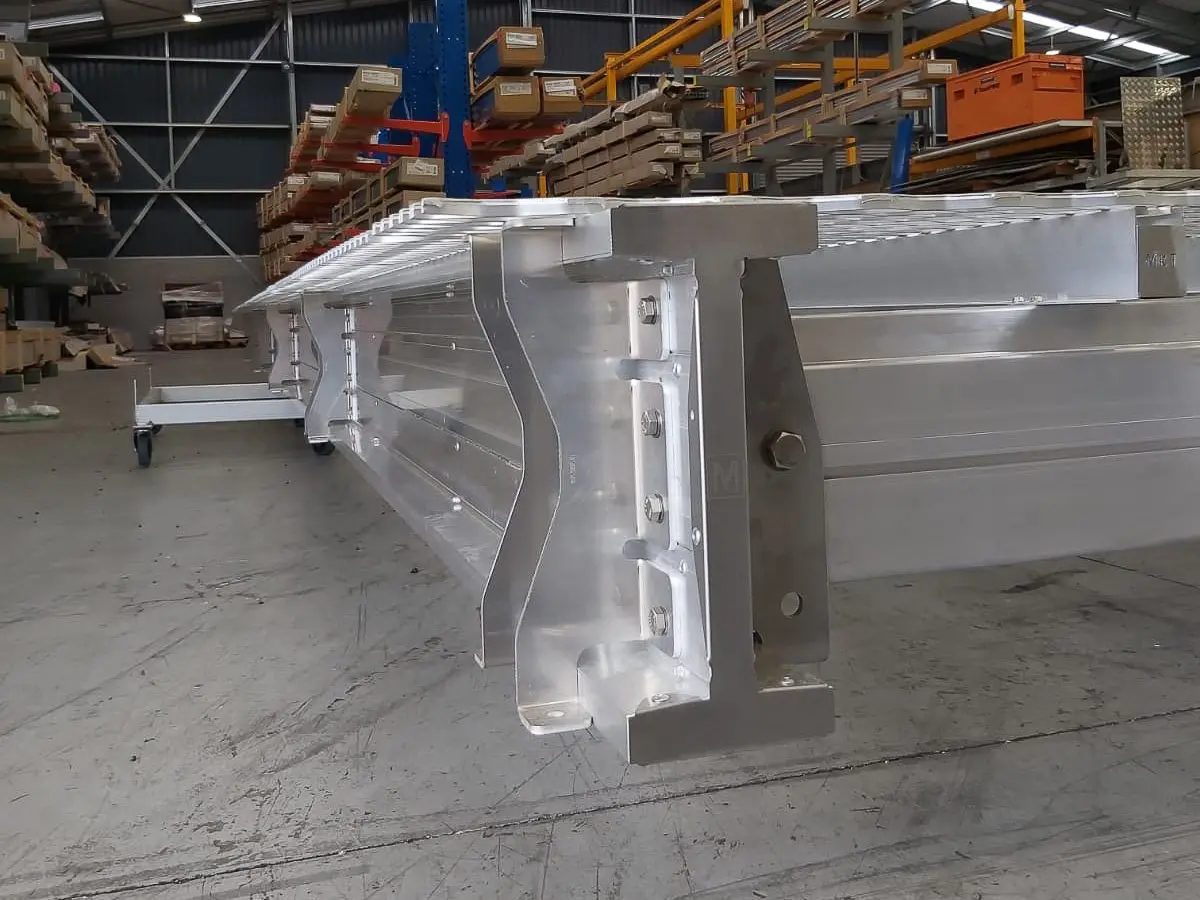

XBeam is made from the combination of 2 technologies, carbon fibre-reinforced polymers and High Tensile T6 Aluminium. Carbon fibre’s strength as a material comes down to the nature of the composite. The ability to tailor the direction of the carbon fibres means it can yield stiffness 20 times greater than a metal baseline. That means carbon fibre structures can span further distances and support greater weights while also weighing less –opening doors for greater designs. This is also suitable for other external long span high load applications where Steel “I beams” are used.

Our Benefits

Lightweight – Up to 65% Lighter than steel equivalent, Less loading on supporting structure.

Low deflection for superior Acoustic performance.

Fully modular Pre-engineered beam system.

Fast install using more off site, pre-assembled packages due to the lightweight, high strength beam. No hot work/Welding is required.

Fully isolated and pre-engineered connections to Portal frames

Fully sealed construction.

XBEAM SOLUTIONS

XBEAM Beam

XBEAM Faster. Lighter. Stronger. Its' the beam, raising the bar. A configurable aluminium beam system utilised in a modular XBEAM platform system.1234[torq_carousel use_both_side_spacing="off" nav_pos_x="0px" _builder_version="4.24.2" _module_preset="default"...

XBEAM Structural Plant Platform

XBEAM Faster. Lighter. Stronger. Its' the beam, raising the bar.A configurable aluminium beam system utilised in a modular XBEAM platform system.1234[torq_carousel use_both_side_spacing="off" nav_pos_x="0px" _builder_version="4.24.2" _module_preset="default"...

SPAN TABLES

Uniformly distributed deUniformly distributed design load capacity (kN/M) with simply supported conditions + full lateral restraint.

(*Bold line indicates difference between shear and bending failure mode.)sign load capacity (kN/M) with simply supported conditions + full lateral restraint.

Uniformly distributed design load capacity (kN/M) for L/250 deflection. Simply supported conditions + full lateral restraint.

(*Values under bold line do not reach deflection limit prior to shear/bending failure.)

Uniformly distributed design load capacity (kN/M) for L/300 deflection. Simply supported conditions + full lateral restraint.

(*Values under bold line do not reach deflection limit prior to shear/bending failure.)

Design moment capacity (kN/M) without lateral restraint.

The Xbeam is highly configurable whereby the carbon fibre quantities can be altered depending on loading requirements. There are currently three main beam height options.

Aluminium vs Steel The Ultimate Showdown

Aluminium has long been seen as a premium, quality product but now its versatility is really being realised. At Monkeytoe, we’re passionate about encouraging ‘Construction Influencers’ to look at the whole picture when it comes to construction, and it’s in this context that aluminium’s true benefits shine.

COMPLIANCE

Physical/Practical load testing of roofing clips witnessed by independent engineers

• Physical in-situ acoustic testing conducted by Norman Disney & Young Consultants.

• Structural design certificate signed off by certified Australian engineer

• ABCB NCC 2019

• AS 1657

• AS/NZS 11170.0 General Principles

• AS/NZS 1170.1 Permanent , Imposed and other actions

• AS/NZS 1170.2 Wind Actions

• AS/NZS 1170.4 Earthquake actions in Australia